"/>

"/>

"/>

"/>

设计机构|milanesi | paiusco

项目类型|工业建筑

项目地点|浙江省,嘉兴市,桐乡市

©山间影像

“未来的工厂能否摆脱生产空间的单调,

成为兼具可持续性、开放性和社会意义的场所?”

©图源网络

在大众印象中,工厂意味着高墙围合、巨大的厂房与永不停止的流水线,长期以来被视为封闭、单调、以效率为唯一目标的空间。在中国,工厂曾长期带有粗糙甚至低级的刻板印象。而在当代,工厂已不再只是生产的容器,而逐渐成为能源转型、生态责任与劳动条件等议题的集中体现。

正如勒菲伏尔在《空间的生产》(1974)中所指出的,空间不是中性的容器,而是社会关系的产物。工业建筑亦是如此,它不仅承载生产流程,也折射出资本逻辑与能源制度。由milanesi | paiusco设计的泰瑞GIGA工厂,正是在这一视角下展开,对工业建筑的过去、现在与未来进行新的思考。

In the public imagination, factories are tied to enclosing walls, vast sheds, and endless assembly lines—spaces long viewed as closed, monotonous, and efficiency-driven. In China, they were once seen as unsightly and low-grade, reinforcing negative stereotypes. Today, however, factories are no longer mere production containers; they increasingly embody questions of energy transition, ecological responsibility, and labor conditions.

As Henri Lefebvre argued in The Production of Space (1974), space is not neutral but produced through social relations. Industrial architecture likewise not only supports production processes but also mirrors the logic of capital and energy regimes. Tederic GIGA Factory, designed by milanesi|paiusco, seeks to reframe how we think about the past, present, and future of industrial architecture.

©山间影像

工业建筑的过去与转折点

The Past and Turning Point in Industrial Architecture

1913年,亨利·福特将流水线与标准化生产引入位于底特律的Highland Park工厂,奠定了现代工业生产的典范。这一空间逻辑极大提升了生产效率,却也将工人彻底纳入纪律化的体系之中,他们被流水线规训,劳动逐渐失去主体性。正因如此,福特制工厂被誉为「生产殿堂」,但同时也成为「劳动异化空间」的象征。

In 1913, Henry Ford introduced the assembly line and standardized production at the Highland Park Factory in Detroit, establishing a paradigm for modern industrial production. This spatial logic dramatically increased efficiency, but it also subjected workers to a rigid disciplinary system—shaped by the assembly line, labor gradually lost its autonomy. Fordist factories were celebrated as "cathedrals of production," yet they also became symbols of the "alienation of labor."

Highland Park工厂纪律化管理体系 ©图源网络

进入后工业化阶段,中国开始面临环境危机与社会诉求的双重压力。过去以牺牲工人福祉和环境为代价换取效率与增长的空间逻辑,正在被不断质疑与修正,更加绿色、人本和可持续的工业转型逐渐成为新的方向。

In the post-industrial stage, China has begun to face the dual pressures of environmental crises and social demands. The spatial logic of pursuing efficiency and growth at the expense of workers' welfare and the environment is being increasingly questioned and revised, while a greener, more human-centered, and sustainable industrial transformation is gradually emerging as the new direction.

可持续与零碳目标

Sustainability and the Net-Zero Goal

在碳中和目标已成为全球共识的背景下,工业建筑因其高能耗与高排放特征,成为能源转型与减碳实践的关键场所。

通过引入光伏发电、可再生能源和循环利用等措施,工厂不再只是能源消耗者,而是逐步演化为具有生产与调节能力的能源节点。

With carbon neutrality now became a global consensus, industrial buildings—characterized by high energy consumption and high emissions—have become critical sites for energy transition and decarbonization.

By integrating photovoltaic systems, renewable energy, and recycling strategies, factories are no longer just energy consumers but are evolving into energy nodes with both productive and regulatory capacities.

©山间影像

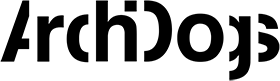

泰瑞GIGA工厂位于浙江省嘉兴市桐乡市经济开发区,占地面积247亩(约164,666平方米),建筑面积244,581平方米。由金加工车间、注塑及压铸机组装车间、办公综合楼、技术研发中心等多功能模块构成。工厂由milanesi | paiusco负责建筑设计,旨在打造一个兼具高效生产与可持续发展的绿色创新型工业园区。建造历时仅1年9个月,这座“零碳”未来工厂于2024年7月正式竣工投产。

Tederic GIGA Factory, located in the Economic Development Zone of Tongxiang, Jiaxing, Zhejiang Province, covering a site area of approximately 164,666 square meters and a gross floor area of around 244,581 square meters. It comprises machining workshops, injection molding and die-casting assembly halls, an office complex, and a testing lab. Designed by milanesi|paiusco, the project seeks to create an innovative green industrial park combining efficient production with sustainable development. After approximately 1 year and 9 months of construction, this "zero-carbon" factory was completed and inaugurated in July 2024.

功能分区 ©milanesi | paiusco

工厂屋顶所设置的11.69MW光伏发电系统,是其绿色能源体系的核心,其年均发电量可达1142.23万kWh,相当于4000户普通家庭一年的用电量。

At the core of its green energy system is an 11.69 MW rooftop photovoltaic array, producing an annual average of 11.4223 million kWh—equivalent to the yearly consumption of 4,000 households.

This system allows the factory to achieve nearly 100% energy self-sufficiency, fully covering operational demand while channeling 37% of surplus electricity back into the grid, contributing to regional renewable supply and advancing the zero-carbon agenda.

屋顶光伏发电系统 ©山间影像

除此之外,工厂还通过雨水收集系统实现水资源的循环利用,用于周边绿化的日常浇灌。厂区周边则规划了小型农业区,不仅为食堂提供蔬菜供应,也兼具绿化功能,同时为工人提供了休闲与体验的空间。

In addition, a rainwater collection and reuse system supports water recycling across the campus. The surrounding area integrates small-scale agricultural plots that supply vegetables for the canteen, add to the site's greenery, and create opportunities for workers' leisure.

©山间影像

建筑语言:功能与美学的融合

Fusion of Function and Aesthetics

工业建筑的外观在很长一段时间里往往被视为附属,呈现出封闭、沉重、缺乏设计感的形象。20世纪初,德国阿尔菲尔德的Fagus工厂以钢结构与大面积玻璃幕墙打破了传统厚重的立面形象,成为现代主义工业建筑的里程碑,为功能与美学的结合奠定了基础。

For a long period, the appearance of industrial buildings was often considered secondary, presenting a closed, heavy, and uninspired aesthetic. In the early 20th century, the Fagus Factory in Alfeld, Germany, pioneered the use of steel structures and glass curtain walls, breaking with traditional heavy forms and becoming a milestone in modernist industrial design—laying the groundwork for the integration of function and aesthetics.

Fagus工厂 ©图源网络

进入当代,工业建筑被赋予了超越单纯生产的意义,其设计与美学不再是附属,而成为承载功能与表达价值的重要方式。

In the contemporary era, industrial architecture has taken on a meaning beyond pure production, where design and aesthetics are no longer secondary but serve as vital means of fulfilling functions and conveying values.

泰瑞GIGA工厂的设计也以自身方式回应了这一趋势——在强调功能与适应性的同时,通过立面、顶面、光线和材料选择展现了简洁、理性的工业美学。

Tederic GIGA Factory responds to this trajectory in its own way—emphasizing functionality and adaptability while articulating a restrained, rational industrial aesthetic through its façade, top surface, lighting, and material strategy.

©山间影像

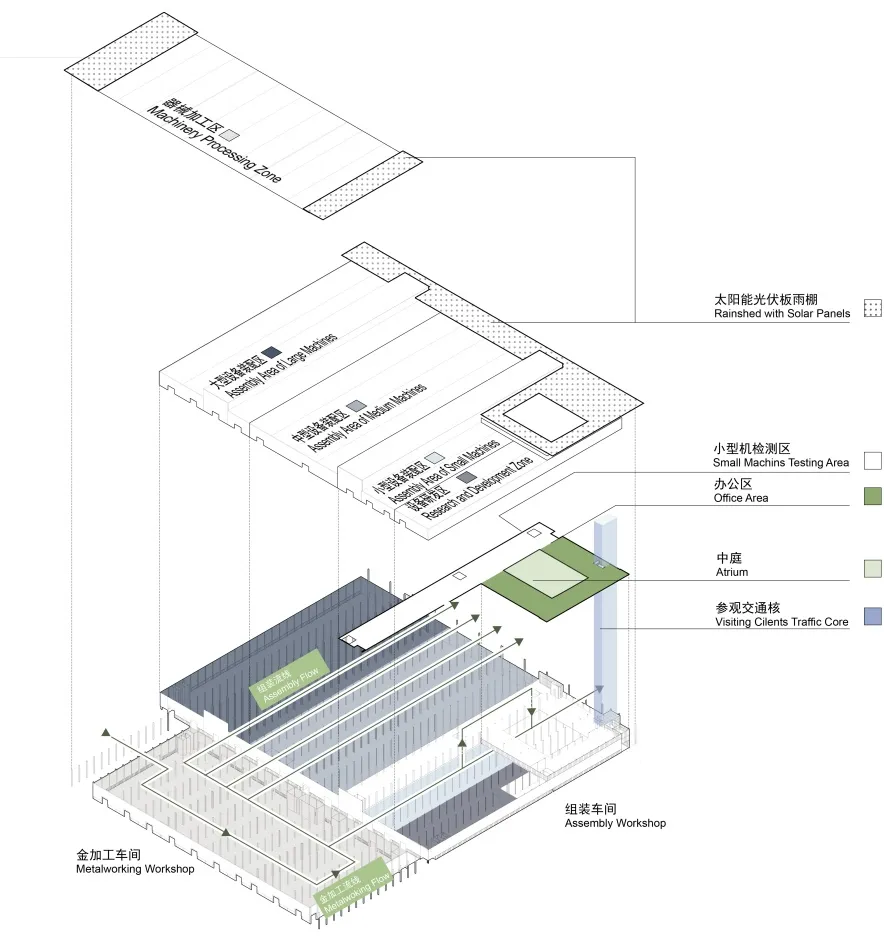

由于客户的生产需求,工厂高度较高、体量庞大。设计通过屋顶及立面虚实的对比处理,使厚重体量在视觉上转向轻盈,不仅保障了卸货作业空间的功能性,也有效削弱了庞大尺度带来的压迫感,增强了通透与开放的空间氛围,让建筑外观摆脱了方正单调的「黑盒子」印象。

The factory's considerable height and mass, required by production demands, are balanced through a design strategy that combines a glazed ground floor with more enclosed upper levels, together with steel-framed canopies and articulated façade layers. These elements ensure the functionality of unloading areas while softening the building's scale, improving spatial transparency, and breaking away from the rigid monotony of a "black box."

©山间影像

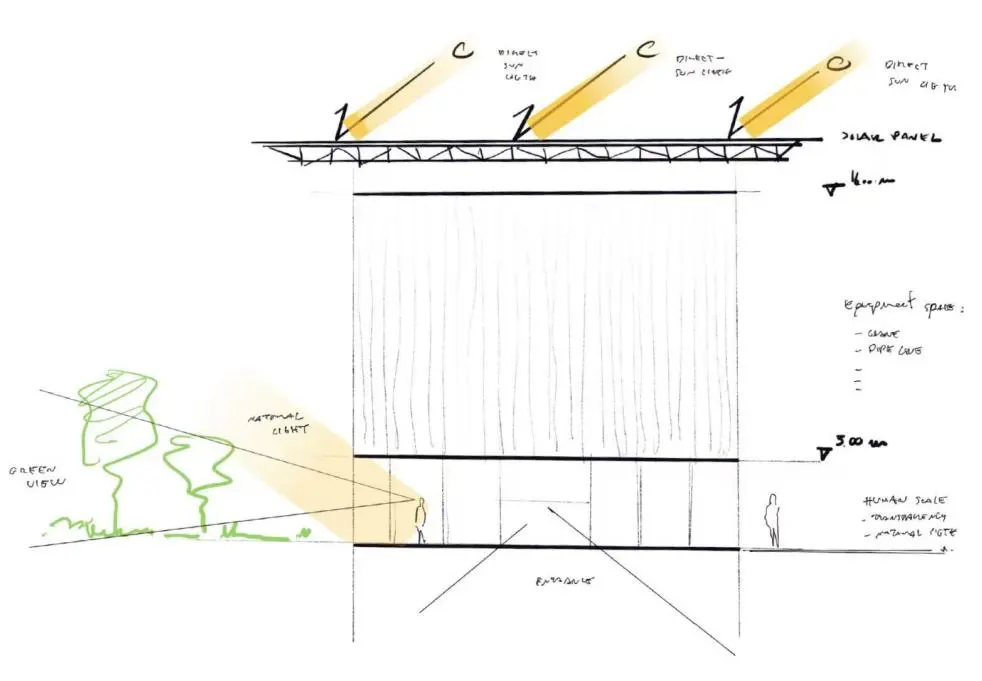

屋顶以及立面通过太阳能板钢架雨篷以及体量的高低错落排布,丰富了建筑的层次关系,进一步弱化了大体量的生硬感,使整体构图更具韵律感与层次感。

The roof and façades, through the arrangement of solar-panel steel canopies and staggered building volumes, enrich the architectural layering, further softening the rigidity of the large mass and bringing greater rhythm and depth to the overall composition.

首层玻璃立面制造悬浮感 ©山间影像

玻璃幕墙与瓦楞板组合立面打破传统封闭模式,实现最大化自然采光,提升空间通透感,降低照明能耗。立面玻璃与瓦楞板的比例配置,使建筑在视觉上竖向缩减约3–4米,有效减轻大体量工业建筑的压迫感,呈现出更为轻盈的效果。

The façade departs from traditional closed models, combining glass curtain walls and corrugated panels to maximize daylight penetration, enhance openness, and reduce lighting energy use. The ground-floor façade employs glass or corrugated steel to visually shorten the building by 3–4 meters, effectively mitigating the oppressive scale of its mass and producing a lighter appearance.

与玻璃相近的反光效果 ©山间影像

非展示区域以不锈钢瓦楞板替代玻璃,使立面保持与玻璃相近的反光效果,确保整体协调统一,同时显著压缩造价。

Non-display areas use stainless-steel corrugated panels instead of glass, maintaining reflective qualities close to glass, ensuring overall visual consistency, while significantly reducing costs.

工厂与工人:人文关怀的空间

Factories and Workers: Human-Centered Care Space

©山间影像

工厂建筑不仅是生产效率的机器,更是成千上万工人日常劳动与生活的空间。传统工厂不仅体现为一种生产模式,也塑造了一种严格的空间秩序:封闭、昏暗、与外部环境隔绝的格局,使工人失去了主体性与舒适感。

然而当代工业建筑正逐渐呈现出新的趋势——在确保生产效率的同时,引入更多自然光线、绿化与景观,使工作环境更加开放宜人,泰瑞GIGA工厂的园区布局正是这一理念的体现。

Factories are not merely machines of efficiency; they are the spaces where thousands of workers spend their daily labor and lives. Traditional factories embodied not only a mode of production but also a strict spatial order: enclosed, dim, and isolated from the environment, stripping workers of agency and comfort.

In contrast, contemporary industrial architecture increasingly seeks to combine efficiency with well-being—introducing daylight, greenery, and landscape elements to create open and pleasant work environments. The layout of Tederic GIGA Factory exemplifies this shift.

高效生产流线

Efficient production flowlines

工厂规划了两大核心生产车间,南侧金加工车间负责零部件的加工和热处理,北侧组装车间自西向东依次布局大、中、小型机装配线。设计采用高效的单向流线体系,使物流动线、生产流线与出货路径紧密衔接,避免回流与交叉,提升整体协同效率并确保顺畅运转。

The factory is organized around two core workshops. To the south, machining and heat treatment; to the north, assembly lines arranged west-to-east by scale (large, medium, small). A streamlined one-way system integrates logistics, production, and outbound flows, minimizing backtracking and intersections, improving coordination, and ensuring efficient operation.

©山间影像

首层落地玻璃

Ground-floor glazing

首层设置3米高的落地玻璃,使车间内部与外部景观相连。打破了传统工厂「黑盒子」的格局,工人能够在日常工作中看见蓝天与绿植,缓解长期处于封闭空间带来的压抑感。

Three-meter-high glass panels connect interiors with exterior views, breaking the "black-box" typology of traditional workshops and allowing workers visual access to sky and greenery, alleviating the psychological burden of confinement.

首层落地玻璃室内视角 ©山间影像

办公区与休憩区

Integrated office and leisure zones

办公区中部挑空形成屋顶阳台,最大化引入自然采光与绿化,不仅提供舒适的绿色休憩与交流场所,也让办公环境与生产空间形成柔性过渡。

A central atrium creates a rooftop terrace, maximizing daylight and greenery. This green respite fosters social interaction and provides a gradient transition between administrative and production spaces.

屋顶阳台 ©山间影像

这种兼顾效率与关怀的设计,不仅改善了工人的日常体验,也间接提升了生产效率与创造力。它将表明,工业建筑中的「软性价值」并非附属,而是推动生产力延伸与创新的关键动力。

Such a balance of efficiency and care both improves workers' daily experience and indirectly enhances productivity and creativity. It underscores that "soft values" in industrial architecture are not peripheral but vital drivers of extended productivity and innovation.

©山间影像

未来图景:工业建筑与社会的关系

Future Perspectives of Industrial Architecture

「更好」并不一定意味着「更贵」

"better" does not necessarily mean "more expensive"

传统工厂

以「成本最低化」为导向

黑箱式车间

只满足生产的基本需求

Traditional factories: Guided by lowest-cost logic, with workshops that satisfy basic production needs.

泰瑞GIGA工厂

更注重「适应性」

功能先行

务实与经济性并存

Tederic GIGA Factory: Prioritizes adaptability, where functionality, pragmatism, and economy coexist.

©山间影像

泰瑞GIGA工厂证明,「更好」并不一定意味着「更贵」。其整体建造成本与传统工厂大体持平,部分环节甚至更加经济。通过合理的规划与材料选择,设计实现了更高的能效、更舒适的空间体验以及更优的环境品质。

Tederic GIGA Factory demonstrates that "better" does not necessarily mean "more expensive." Its overall construction cost is broadly comparable to that of conventional factories, with certain aspects proving even more economical. Through rational planning and material choices, the design achieves higher energy efficiency, more comfortable spatial experience, and improved environmental quality.

©山间影像

未来的工厂,不再是隐匿于城市边缘的生产装置,而是社会运行的重要节点。工业建筑应该回应具体语境与生产逻辑,而不是追求普适的「最佳方案」。它们将同时承担制造、能源、生态与文化的多重使命,成为定义未来城市与社会关系的新型基础设施。

The factory of the future will no longer be a concealed device on the urban periphery but a critical node in social and ecological systems. Industrial architecture should respond to specific contexts and production logics, rather than seek universal formulas. It will simultaneously serve as a site of production, an energy hub, an ecological laboratory, and a cultural platform—reshaping the relationship between cities, societies, and industry.

©山间影像

项目信息

项目名称:泰瑞GIGA工厂(桐乡)

项目地址:浙江省嘉兴市桐乡市

项目业主:浙江泰瑞装备有限公司

设计时间:2022年4月 - 2024年2月

建造时间:2022年10月 - 2024年7月

用地面积:164,666平方米

建筑面积:244,581平方米

项目设计:milanesi | paiusco

主创设计师:Claudio Milanesi、Diego Paiusco

建筑设计团队:李哲桢、唐得智、李东洋、蔡舜欣

项目&设计管理:milanesi | paiusco

图片版权:山间影像、milanesi | paiusco

Project Information

Project name: Tederic GIGA Factory (Tongxiang)

Project location: Tongxiang, Jiaxing, Zhejiang

Project client: Zhejiang Tederic Equipment Co., Ltd.

Design year: April 2022 - February 2024

Construction time: October 2022 - July 2024

Site area: 164,666 sqm

Gross floor area: 244,581 sqm

Project design: milanesi | paiusco

Chief Architect: Claudio Milanesi, Diego Paiusco

Design team: Li Zhezhen, Tang Dezhi, Li Dongyang, Cai Shunxin

Project & Design management: milanesi | paiusco

Photo credit: Shan-jian images, milanesi | paiusco